LIVE – METALISM

PRODUCTS

HOME > Product Range > Heat Resistance

HEAT RESISTANT CASTING ALLOY

Metal material which stand high temperature use.

This is what required in high intense heat industries who are making remarkable innovation, especially by iron mill.

Responding such requirement we have develop many ultra heat resistant materials based on our experience and technologies in many years.

(Characteristics of wear resistant, oxidation resistant, corrosive resistant, creep strength, high rigidity and thermal shock resistance.)

High performance heat resistant steel

| PSMT26 | Ni based high corrosive resistant material(~1100℃) |

|---|---|

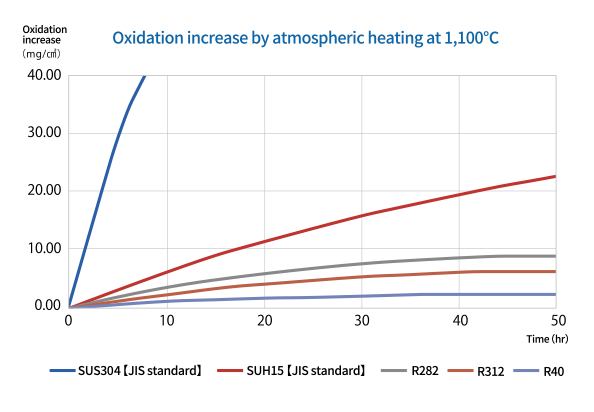

| R40 | High wear resistant steel (~1100℃) |

| R312 | High wear resistant steel (~1200℃) |

| R262 | High wear resistant steel (~900℃) |

| NWA15 | High oxidation resistant steel (~1000℃) |

| NWA13改 | High oxidation resistant steel (~1100℃) |

| NAX-TR | High temperature high strength steel (~1100℃) |

Heat and wear resistant steel

| G | High temperature wear resistant steel (~900℃) |

|---|---|

| HP3 | High temperature oxidation resistant steel |

| HP10 | Thermal resistant steel equivalent to SCH12 |

| HP12 | Thermal resistant steel equivalent to SCJ13 |

| HP22 | Thermal resistant steel equivalent to SCH22 |

Tensile strngth at 1000℃ (reference data)

| Grade | Composition | Tensile strength (MPa) | Elongation (%) | Reduction of Area (%) | Application |

|---|---|---|---|---|---|

| PSMT-26 | Ni base | 123 | 41 | 50 | Glass fiber manufacturing parts |

| R-40 | Fe base | 66 | 10 | 16 | Heating furnace hot zone (1200℃) Skid rails |

| R-312 | Fe base | 50 | 69 | 70 | |

| JIS standard product【SUS310S】 | Fe base | 46 | 109 | 68 | Heating furnace material and equipment etc. |

PRODUCT RANGE

Product Range

Accumulated R&D effort and crystallization of refined technology.