LIVE – METALISM

OCCUPATION

HOME > List of Equipment’s > Manufacturing equipment

Manufacturing equipment

Responding Customer Needs with Developing Special Alloy.

World Leading Manufacturer of Low Thermal Expansion Alloy.

High-frequency induction melting furnace (3t, 1t, 700kg, 500kg)

Up to 4t melt can be made with using 3 furnaces simultaneously

High-frequency induction melting furnace 100kg for test

This furnace is used for new alloy or technical development and small size cast operation.

Self-hardening molding apparatus 20t/10t/5t

A part of alkaline phenol self-hardening process.

Used for mainly 0.5t to 4t middle to large size molding.

Raw type molding apparatus

Used for 500 x 700 x Height size mass production

Vertical centrifugal casting equipment

Up to φ650 x H700 circular product, height quality casting can be made.

Self-hardening molding apparatus line

Alkaline phenol self-hardening process

Capacity of input sand volume : 5t/h

Semi-automatic molding line

Self-hardening sand shake out machine

Used for breaking shell mold made by alkaline phenol

Shake out machine just for raw mold

Sand recycling for raw mold

Shot blast machine

Quick surface cleaning with blasting small steel bolls

Max wt.=5ton Size=Φ2500xH3000

Tumbler shot blast machines

100kgs and 200kgs machines are used

Swing grinder

7.5kw x 3 units

3.7w x 3 units

Double heeded grinder

2 machines are used

Efficient for finishing of handy type products

Hydraulic 500kn Press

5000KN Head moving type=3500Dx3400Wx650H

5000KN Head fixed type =3500Dx2400Wx1200H

High temperature heat treatment furnace with 7t truck

Heat treatment temperature : Max. 1150℃

Size : 2300D x 2000W x 1500H

High temperature heat treatment furnace 3t by batch

Heat treatment temperature : Max. 1250℃

Size : 1350D x 1800W x 700H

Low temperature heat treatment furnace with 5t truck

Heat treatment temperature : Max. 400℃

Size : 3500D x 3200W x 1600H

Tig welders

200A x 1 unit

300A x 5 units

Air compressors

75kw x 1 unit

37kw x 1 unit

11kw x 1 unit

Dust collectors

785m3 x 1 unit, 600m3 x 1 unit,

400m3 x 2 units, 190m3 x 1 unit,

140m3 x 1 unit, 120m3 x 2 units

Crane equipment

7.5t x 1 unit, 4.8t x 2 units

2.8t x 8 units, 2t x 1 unit

Demand management facility

Latest electricity monitoring system is adopted.

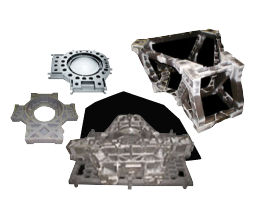

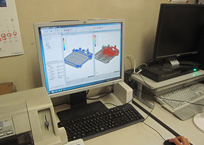

Casting simulation device

This is for checking of casting design and method.

Analysis of molten metal flow

Analysis of metal solidification

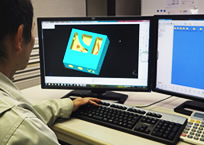

Three-dimensional CAD equipment

Adopted software : NX, NX-Ideals and SolidWorks

Any 3D data can be applicable

Centerless polishing machine

Applicable size = φ0.8 to φ25

In case 0.4mm thickness polishing margin, shorter lead time is available.

Polishing of forged material can be made.

(Alternative materials)

Titan alloy

Hastelloy alloy

Inconel alloy

Straight rod roll straightening machine

Applicable size = φ3 to φ25br />Rough surfaced forged surface material also can be formed.

Linear cutting machine

Applicable size : φ0.8 to φ2.8

Correction and linear cutting can be made from coil

PRODUCT RANGE

Product Range

Accumulated R&D effort and crystallization of refined technology.