LIVE – METALISM

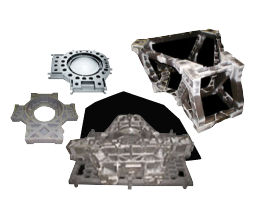

OCCUPATION

HOME > List of Equipment’s > Inspection and Analysis

Inspection/Analysis

Responding Customer Needs with Developing Special Alloy.

World Leading Manufacturer of Low Thermal Expansion Alloy.

Responding trend of times, required quality level become severe and severe. We have established strict quality control (or assurance) structure by not only dimension measurement and visual inspection but also chemical composition of products has been analyzed by chemically and mechanically. CMM(Co-ordinate Measuring Machine) and X-ray non-destructive testing equipment are also adopted. We acquired ISO9001and strengthen our effort to upgrading our quality control and assurance to serve our product to our customers. Through our activities, It is our pride when if we could have our customers trust and satisfaction.

InspectionAdvanced analysis can be made with state of the art facilities.

Inspection method is differ in each product characteristics. Inspection from many angles has be made to cope with our customer’s requirement. We have been making precise inspection to serve our product in best condition by maintaining quality level and with latest equipment.

CNC gate-type three-dimensional measuring machine

Range of measurement : X1200 x Y2000 x Z1500

Accuracy of measurement : 3.5 + 5L/1000μm

Minimum display : 0.01μm

Horizontal arm-type three-dimensional measuring machine

Horizontal arm CMM

Range of measurement : X1480 x Y2150 x Z1500

Guarantee accuracy : 40μm

Minimum display : 10μm

Articulated three-dimensional measuring tester

Range of measurement : 3.7m (12 feet)

Fixed point repeatability

Measurement accuracy (between 2 points) : ±91μm

Layout machine

Range of measurement : X1480 x Y3600 x Z1500

Guarantee accuracy : 80μm

Minimum display : 10μm

Precision stone surface plate

Size : 1500 x 2000mm

Grade : 00 class (5μm)

Large test assessment board

Size : 3000 x 3000

Size : 1500 x 2000

size : 1500 x 3000

X-ray inspection apparatus (equipment)

Output voltage : 40 to 320kv

Inspection size : 500 x 1500 x 800H

Penetration capability : Iron 60mm

Digital ultrasonic inspection detector

Ultrasonic non-destructive inspection device

Type : UI25 (JSDN featured)

Analysis

Inductively coupled plasma optical emission spectroscope (ICP-OES)

When an atomized sample is sprayed on a plasma that is ionized by inductively heating the gas, a spectrum depending on the element is generated by the excitation of atoms. ICP-OES can qualitatively and quantitatively analyze the elements by distinguishing strength of the spectrums.

Fluorescent x-ray analyzer

Analyzer for measuring each element content of individual test pieces

Milling machine

A milling machine which finishes sample surface for component analysis uniformly by Fluorescent x-ray analyzer.

Spectrophotometer

By measuring penetrated irradiated light of color reacted solution dissolved by acid.

Carbon and sulfur analyzer

Burning drilled chips by high-frequency heating and analyzing quantitatively for oxide out of carbon and Sulphur by infrared -absorbing method.

Chemical analysis pre-treatment facility

Pre-treatment facility before chemical analysis of cutting chip in dissolved in acid.

PRODUCT RANGE

Product Range

Accumulated R&D effort and crystallization of refined technology.